When it comes to glamor, industrial lighting may not rank in the top ten. However, the right lighting around the engine must be a vital attention to any industry. Those who work with exercise, suppressors, and lathes are very aware of the dangers involved, and poor lighting makes work more difficult and dangerous. The association of industrial accident prevention notes that the right workplace lighting is very important for your business, both for the safety and comfort of your workers and as a matter of regulation. According to IAPA, the right lighting at work, including high-quality industrial machine lights, is important for a number of reasons.

* The right lighting allows employees to work more comfortably without risking their eyes or bodies.

* Good lighting prevents expensive – both in monetary and human beings – accidents and errors.

* The right engine lighting increases productivity because workers can work faster and more accurately when they don’t have to be menguriguraan to see what they do.

* Good lighting tasks – and most industrial machine lighting is lighting tasks – it can even help reduce absence at work by reducing injury due to accidents and tensions.

In short, providing adequate lighting for industrial applications is not just a matter of meeting regulations. The right industrial engine lighting prevents accidents and injuries, which saves your business money. It reduces eye fatigue, which means your workers tend to headaches that slow down their work and make them tend to make mistakes.

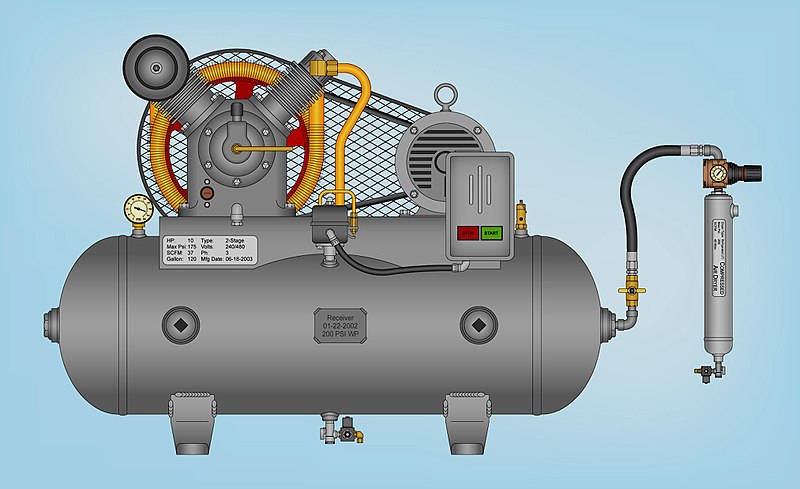

Even so, find the right mill, drill lights or press lights are not always easy. Heavy machines produce strong vibrations, which shortens the life of the light bulb. Industrial machine lights are also at risk of being destroyed if they are hit by bits and pieces of ground or metal are removed by drill or lathe. They can also destroy if they are splashed by chemicals used in the manufacturing process. That is why it is important that each lamp installed on industrial machines is made to withstand the most common dangers they will meet.

Dur-a-Lite industrial machine lights are specifically designed for use on and around heavy duty machines. How? Each light is wrapped in heavy and heavy residential housing that protects the bulbs of shocks and vibrations that are common for heavy industrial applications such as forging, stamping and drilling. They are available in various sizes to suit most standard machines and can be ordered with machine bracket machines, magnet mount or direct installation.

In short, machine lights such as Dur-A-Lite are ideal illumination solutions for factory and industry applications where ambient standards and task lighting is not enough. But the right position is the most important. These tips can help ensure that your workers can easily see materials and machines with which they work,

* Position the lighting unit so that 90 to 100 percent of the light is directed to the work area.

* For industrial use around heavy machinery, lights must provide 3,000 to 10,000 lumens for safety.

* Know that glare can cause visual fatigue. Environmental changes, such as brightly colored matte walls, can reduce glare.

* Train workers how to adjust the right lighting in their work. Make check and adjust the machine parts part of the tool settings process for each shift and new worker.

The right industrial machine lighting reduces accidents, making work easier and increasing productivity. Choose the machine lights carefully to ensure that your worker always has the light they need to do work safely.