One of the most pressing questions regarding today’s rapidly evolving technological landscape is: what roles can cobots play in helping us humans? In recent years, robotics and artificial intelligence advancements have resulted in cobots, which combine humanoid capabilities with enhanced levels of digital intelligence and industry-grade hardware.

While these machines present many potential risks to human workers if not managed properly when used responsibly, they also offer many opportunities for productivity gains, increased safety protocols, and improved ergonomics—benefits that even the most tech-averse can appreciate. Here, we will explore how cobots impact business operations worldwide and dive into some exciting examples proving their utility on factory floors and industrial workplaces.

The concept of cobots and their role in aiding humans

The word “robot” evokes images of cold, metallic beings toiling away in factories or laboratories. But a new type of robot has emerged in recent years: the collaborative robot, or “cobot” for short. These robots are designed to work alongside humans, assisting with various tasks and making our lives easier. The concept of cobots is a fascinating one, as it has the potential to revolutionize the way we work and live.

By providing an extra set of hands, cobots can help increase productivity, improve safety, and reduce the risk of repetitive strain injuries among workers. In this way, cobots are efficient machines and valuable partners in our day-to-day operations. As we continue to develop and refine the technology behind these cobots, their role in aiding humans will only become more significant.

How cobots are being used in factories to increase efficiency

One of the most common places where cobots are utilized is factories. These machines have been integrated into manufacturing processes to perform various tasks, such as assembly, packaging, quality control, and material handling. By automating these repetitive and often physically demanding tasks, cobots can help increase efficiency and reduce business costs.

Cobots are also highly versatile and can be easily reprogrammed to perform different tasks, making them valuable for manufacturers looking to adapt to changing market demands. Instead of investing in new machinery or hiring additional workers, cobots offer a cost-effective solution that can quickly adjust to any production needs.

The safety benefits of using cobots for repetitive tasks

Repetitive tasks are a necessary component of many industries but can pose significant health risks to workers. These types of tasks often involve repetitive motions, awkward postures, and heavy lifting, which can lead to musculoskeletal disorders and other workplace injuries. However, with the use of cobots, these risks can be significantly reduced.

Cobots are equipped with advanced sensors and safety features, such as force-limiting technology and collision detection, which allow them to work safely alongside humans. By taking on these repetitive tasks, cobots can help improve workers’ overall health and well-being, reducing the likelihood of workplace injuries and improving employee satisfaction.

How cobots can help in medical care settings and other areas

While most cobots are currently being used in industrial settings, there is also great potential for their use in other areas, such as healthcare. Cobots can assist with tasks such as lifting and moving patients, helping to reduce strain on medical staff and increasing efficiency in patient care. They can also be used in hazardous environments, such as cleaning up after a chemical spill or assisting in disaster situations.

Cobots are also entering the hospitality industry, where they can handle food preparation and customer service tasks. By taking on these repetitive and physically demanding tasks, cobots can help alleviate some of the burden on human workers, allowing them to focus on more complex and meaningful tasks.

Strategies for integrating cobots into existing work environments

As with any new technology, integrating cobots into existing work environments requires careful planning and consideration. Businesses must assess their current operations and identify areas where cobots could be utilized to improve efficiency and safety.

One key strategy for successful integration is to involve workers in the process from the beginning. Employees can feel more comfortable and confident in their interactions with these machines by providing training and education on how to work alongside cobots. It can also help to alleviate any fears or concerns about job displacement.

Another strategy is to start small and gradually introduce cobots into the workplace, giving employees time to adjust and learn how best to work alongside them. By taking a phased approach, businesses can identify potential challenges and make necessary adjustments before fully integrating cobots into their operations.

Conclusion

We expect to see even more sophisticated cobots entering the market as technology advances. These machines will not only be able to assist with physical tasks but also take on more cognitive functions, such as problem-solving and decision-making. It opens up endless possibilities for collaboration between humans and cobots, leading to increased productivity and improved quality of life for workers.

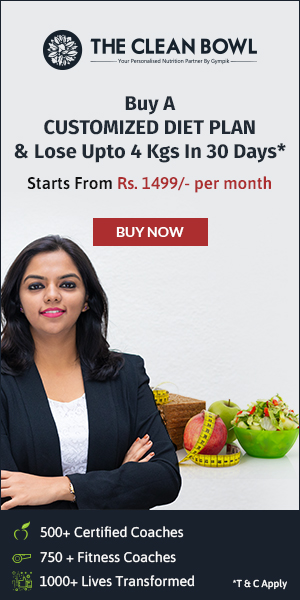

Infographic created by Acieta, highlighting the importance of robotics to nearly every industry